3d Printed Gear Teeth Design

Switch gears now: up to 80% more wear-resistant than conventional plastics

Gear CAD configurator

No CAD model at hand? With our gear configurator, you can create a gear model with individual dimensions in less than 60 seconds.

Configure gear CAD

Free gear sample

Still not convinced? See for yourself: we will gladly send you a free gear sample.

Request sample part now

Gear service life calculator

How long does a 3D printed gear last? Simply enter the parameters of the application and then calculate the foreseeable service life with just a few clicks of the mouse.

To the service life calculator

Plastic gears on the test rig

Tested and proven: iglidur gears have five times the service life of machined gears made of standard plastics.

- iglidur I3 is characterised by higher strength, is especially well-suited for spur gears and helical-bevel gears, and can be used for all other kinds of wear-resistant gears.

- iglidur I6 has optimised sliding properties and is therefore ideal for worm gears or other gears where conformity with food standards is required.

- iglidur I8-ESD is suited to gears that require ESD properties, such as those used in ATEX machines

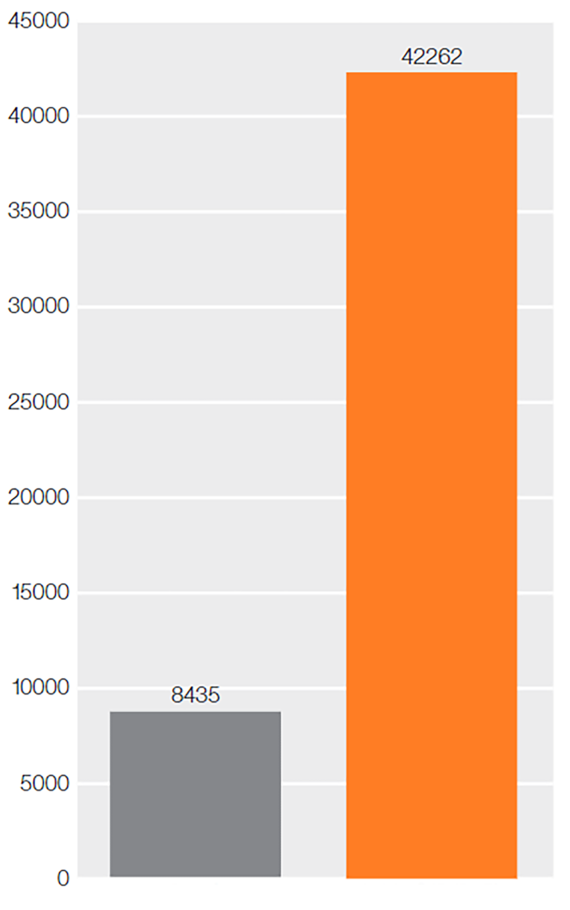

Gear test: cycles until gear breakage

iglidur I3 (laser sintered) vs. POM (machined)

In this test, a gear drives a rack, and the number of cycles completed before the gear breaks is recorded. Gears 3D printed or laser sintered from iglidur lasted five times as long as gears milled from POM.

Pivoting 1440°: n = 64rpm, M = 2.25Nm, z = 30, m = 1, b = 6.5mm

- POM (machined)

- iglidur I3 (laser sintering)

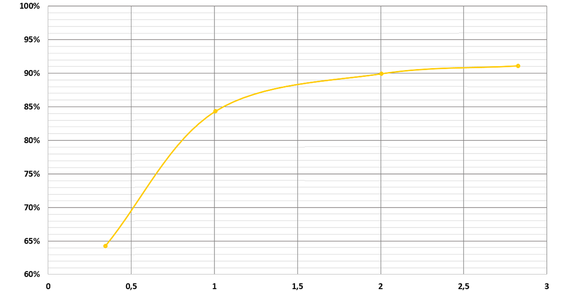

Very high efficiency for 3D printed gears made of high-performance polymer

Planetary gearbox efficiency testing showed that gears laser sintered from iglidur I3 had efficiency in dry operation comparable to that of oil-lubricated metallic planetary gearboxes. How can that be? The solid lubricants contained in iglidur polymers greatly reduce the coefficient of friction so that dry-operating 3D printed iglidur gears achieve an efficiency that is only slightly lower than that of lubricated metal gears. Integrated lubrication greatly reduces maintenance effort.

Test procedure: the gearboxes are tested on a dynamometer. The gearbox is driven by a stepper motor and an electromagnetic brake. Measuring systems in the power train continuously measure the angular position at the gearbox input and output. This allows us to gather efficiency, torque fluctuation, and backlash performance data in practical torque and speed ranges.

► Planetary gearbox transmission 4:1 with iglidur I3 gears in dry operation

Extremely long service life of worm gears with optimised sliding properties

Test parameters:

- Torque: 4.9Nm

- Speed: 12rpm

- Counter partner: hard anodised aluminium

- Duration: two months

Evaluation

► POM (machined): complete failure after 621,000 cycles

► iglidur I6 (sintered): low wear afterone million cycles

Customer application examples

3D printed polymer gears in use

Drive unit printed in 3D for a medicine dispenser

JDM Innovation GmbH presents a new medicine dispenser which automatically dispenses medication in individual packets. The drive components consist of a bevel gear and a linear drive - both components are 3D printed which makes it possible to consider dispensers with small installation space. In addition, 3D printing makes it possible to mass-produce the dispensers and ensures a maintenance-free service life beyond five years.

Gear printed in 3D for astrophotography

A revolving device, together with a camera and telescope, has to compensate for the earth's rotation in order to take long-exposure photos of celestial bodies. The gear wheels for the transmission come from the 3D printer. The tribofilament iglidur I150 ensures a precise and stable rotation of the device. In addition, the design freedom offered by 3D printing made producing the parts simple and quick. The whole thing is controlled with a touchscreen on the outside.

Gears printed in 3D for water cannons on a fire engine

For repair of the roof-mounted cannons of airport fire engines, the on-site fire brigade at Fraport AG needed individual gears that could withstand the high loads. As a manufacturing method, 3D printing makes it possible to produce individual and special parts cost-effectively and quickly. Specially developed for demanding applications in machines, iglidur polymers contain solid lubricants that make them more durable and reduce maintenance work/expenditure.

More about gears printed in 3D in an application example

Vintage spare parts from the 3D printer

Finding spare parts for vintage cars and rare models today is difficult, if not impossible. When a shaft with a worm gear and toothed gear in the mileage counter of the speedometer wore, the owner of a Stanley 750B from 1924 could rely on the online 3D printing service from igus. Due to the abrasion-resistant SLS polymer iglidur I6, a fully functioning spare part was made via laser sintering.

3D printing service for vintage car spare parts

Ten times more cost-effective than usual - replacement gear for tractor

The igus cleaning team tractor was defective for a year as a gear was worn out. The gear made of regular plastic was part of the tractor's starter mechanism, and had broken due to the high load when the engine was started. Shortly before the utility vehicle was scrapped, the 3D printing team came into play and was able to trace the gear and print it within a matter of hours. The tractor is now working perfectly. The gear was made of iglidur I3, and combines a high wear resistance with good mechanical properties. The SLS powder can be processed very precisely, allowing for an exact copy of the complex spindle geometry in the gear's interior.

More about 3D printed gears

Gear made of iglidur I6 for an electric car charging system

Easelink, a company from Graz, has developed "Matrix Charging", a charging system that automatically connects the underside of parked electric cars with the power supply. To design the system to be both economical and high-quality, the designers have chosen gear prototypes made of iglidur polymers with additive manufacturing. The igus 3D printing service allowed sample components to be quickly ordered, tested and adjusted until the ideal solution was reached. The particularly wear-resistant and self-lubricating SLS powder iglidur I6 is ideal for the construction of gears, pinions and other highly stressed components, which usually have to be regularly lubricated, maintained and frequently replaced.

More about polymer gears in the charging systems of electric cars

Polymer pinion for engine tuning

The Formula Student Team from Weingarten near Ravensburg needed, amongst other things, customised polymer pinions to construct their racing cars. The pinions were used as chain tensioners in the chain drive, so they had to be especially robust. The igus 3D printing service allowed polymer pinions to be delivered and tested in less than 72 hours. The material used was iglidur I6, which is especially wear-resistant - it was still fully functional after one million cycles in laboratory tests. In this case, the special parts from additive manufacturing were not only available much faster, but were more robust and economical.

3D printed plastic pinion for a race car

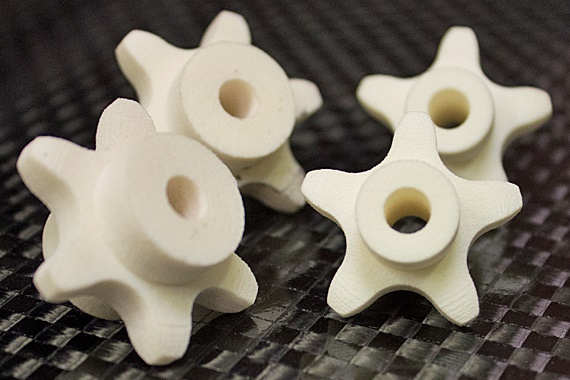

Polymer sprockets made with additive manufacturing for quiet e-bikes

Tough, wear-resistant, lubrication-free: polymer beats metal

For constructing e-bikes it is especially important that the components used are light and quiet. Lars Hartmann from the VMA Getzmann GmbH, which produces stirring, dispersing and fine-grinding systems, tested sprockets printed in 3D made of iglidur I3 as replacement for metal sprockets and was enthusiastic:

"The standard metal pinion generates a lot of noise when in use. We drew it and had igus® print it from iglidur® I3. Getting the part was simple and fast. We used the 3D printing service to upload the corresponding data, chose the material and ordered the quantity."

3D printed polymer sprocket

Enhanced performance with replacement gears

The manufacturer was unable to supply spare parts for the worn gears of a planetary gear in an electric bicycle. The customer eventually contacted igus GmbH's 3D printing department. After receiving the worn parts, the department made a drawing of the gears and printed them from iglidur I3. The tribologically optimised material's abrasion resistance now ensures that the e-bike works again flawlessly, and performance has even been enhanced.

More about 3D printed gears

Previous Next

New: injection-moulded iglidur gears

Gears that are cost-effectively injection moulded from xirodur B180 require no additional lubricant.

Advantages at a glance

- Cost-effective thanks to injection moulding

- Maintenance-free thanks to the iglidur® materials used

- Long service life

- Very low coefficient of friction

Injection-moulded gears

Types of gears

With the igus 3D printing service, every type of wear-resistant and self-lubricating gear drive can be produced quickly and independently of mechanical tools. In addition to conventional models such as spur gears, worm wheels and bevel gears, the laser sintering procedure with iglidur materials works very well for elliptical gears, crown gears, racks, worm gears and much more.

Bevel gear

3D printing news

Innovations in the field of industrial 3D printing. New products and services for additive manufacturing with wear-resistant polymers.

Our innovations at a glance

FAQ: Your most frequent questions and our answers

3D printed gears made of iglidur polymers

What type of lubricant should be used for 3D printed gears?

► You do not need a lubricant for 3D printed gears made of iglidur polymers. The gear already contains lubricant.

Does wear have an effect on the estimated service life displayed in the online service life calculator?

► Unlike the situation for bearings, wear is not the biggest problem for gears. For gears, the question is when the teeth will break off. That determines a gear's service life.

What tolerance does the laser sintering process achieve? How great is the precision of these 3D printed parts?

► Tolerance depends on part dimensions. Parts up to 50mm have a tolerance of ± 0.1mm. Parts larger than 50mm have a tolerance of ± 0.2%. These values apply to non-reworked parts.

To ensure a good fit, should the hole be made smaller and the gear pressed on?

► For the dimensioning of the fit on your shaft, it is necessary to know how torque is transmitted and what mechanism is used. If the shaft is 10x10mm, for example, a tolerance limit of 10.1mm would work for your gear.

Does the gear service life calculator work with small gears (with 12 teeth, for example)?

► Our calculation tool works only for gears with at least 17 teeth. Less than 17 teeth would require undercut information for the calculation, and our calculator has no option for adding or using it. If you need a gear with fewer than 17 teeth, contact your igus representative.

Can threads be cut into a part printed from iglidur?

► Yes, you can machine the parts if you need to.

How much abrasion is there? Do you account for any type of lubrication in your service life calculation?

► Our gear service life calculation assumes that there is no additional lubrication.

Can small worms and worm wheels be 3D printed?

► Our minimum wall thickness is about 0.7mm. If necessary, we can go as low as 0.5mm. We can manufacture small worms and worm gears. If you have high loads, you will need metallic worm shafts.

Can teeth be adjusted (profile adjustment)?

► We can print parts for which the teeth have been adjusted. This is not currently reflected in our configurator. If you need such gears and have no capability for designing them, don't hesitate to contact us.

Are the 5Nm applied to the tooth tangentially?

► The 5Nm are applied to the entire gear, not to the teeth.

Is there a tool for generating the gear/tooth geometry (input module, number of teeth)?

► You can use our gear configurator to create your gear

How do I get gears with a low number of teeth, e.g. ten teeth?

► We have extended our gear configurator, so that it is now possible to configure gears with a minimum number of eight teeth.

Is there a price advantage for reduced 3D printing volumes?

► There is a small advantage if you do not consider the printing volume.

Are iglidur 3D printing materials for FDM suited only to prototypes, or do they perform well enough to be used as functional parts?

► iglidur FDM materials are good for bearings and other wear-resistant parts. Gears made of our laser sintering materials have a much longer service life.

Are machine tapers an option, or do the solid lubricants pose a problem?

► The finished product can be machined like any conventional plastic.

Can I buy iglidur filaments to use in my own printer?

► Yes, you can buy the filament online. Pay attention to the processing instructions, since many of our filaments require closed and/or high-temperature printers

Is there a lower size limit?

► Our minimum wall thickness is 0.7mm. If we need to, we can go as low as 0.5mm, but we normally recommend a minimum of 0.7mm.

Is there test data about wear that compares 3D printed igus gears to other machined plastic gears?

► We have tested many gears made of various POMs and other machined gears such as PPT, but the results were not better than those for POM in any respect.

Is there an optimum shaft-hub connection for parts printed in 3D? I can imagine that a feather key would not be ideal due to the stress concentration.

► The general rule for 3D-printed or polymer bearings is: if the application and load are not very great, the parts can be made of polymer. This rule also works very well for parts printed in 3D. But if the load or surface speed is very high, there comes a point at which the application will work only with a metal part running against a polymer part. At a certain point, it is better to have a metallic shaft because it conducts the heat from the tribological system better. Then the smaller gear should be made of metal because it is always the one with the greater load. The larger gear can be made of polymer, so the system remains without lubrication.

How can gear materials be best combined?

► Both gears can be made of polymer and our service life calculator used to determine the point at which the system stops functioning well. There will be a point at which polymer gears no longer function well because the load is too high.

Doesn't the laser sintering/FDM heat affect the self-lubrication?

► No, it doesn't. The solid lubricants are not affected by the heat. The same is true for injection moulding and bar stock materials, which also experience intense heat briefly during the manufacturing process without losing their self-lubricating properties.

Can metal gears be replaced by 3D printed iglidur gears?

► Metallic gears can handle higher loads that polymer ones can. If you have a metal gear that is reaching the limits of what a metal gear can do, you cannot replace it with a polymer gear. That would require a gear three or four times the current size. But if the metallic gear is not at the limit of what metallic material can do, you can, of course, replace it with a polymer gear, and then you have a system that requires no external lubrication and for which you can receive any type of gear very quickly. You can use our service life calculator to determine whether this is the case for your application or not.

Are printed gears solid?

► All parts printed at igus are solid, so they are 100% polymer and can be reworked. We produce solid parts because they are used as gears, bearings and whatever else in machines, and must therefore have the highest possible stability. You can, of course, also design lightweight components to reduce weight. If that is what you want, let us know, and then we won't print solid gears.

What roughness does 3D printing achieve?

► Sintered material is fairly rough, but smooths quickly during use, and the roughness does not impair the printed part's performance.

The terms "igus", "Apiro", "CFRIP", "chainflex", "conprotect", "CTD", "drygear", "drylin", "dryspin", "dry-tech", "easy chain", "e-chain", "e-chain systems", "e-loop", "e-ketten", "e-kettensysteme", "e-spool", "e-skin", "flizz", "ibow", "igear", "iglidur", "igubal", "kineKIT", "manus", "motion plastics", "pikchain", "plastics for longer life", "print2mold", "readycable", "readychain", "ReBeL", "robolink", "speedigus", "tribofilament", "triflex", "xirodur" and "xiros" are legally protected trademarks of the igus® GmbH/Cologne in the Federal Republic of Germany, and, where applicable, in some foreign countries.

igus® GmbH points out that it does not sell any products of the companies Allen Bradley, B&R, Baumüller, Beckhoff, Lahr, Control Techniques, Danaher Motion, ELAU, FAGOR, FANUC, Festo, Heidenhain, Jetter, Lenze, LinMot, LTi DRiVES, Mitsubishi, NUM, Parker, Bosh Rexroth, SEW, Siemens, Stöber and all other drive manufacturers mentioned on this website. The products offered by igus® are those of igus® GmbH.

3d Printed Gear Teeth Design

Source: https://www.igus.eu/info/3d-print-gears

Posted by: summeyarmorthavins51.blogspot.com

0 Response to "3d Printed Gear Teeth Design"

Post a Comment